Product Quality and Safety

Our commitment to the quality, safety and integrity of our products is at the heart of everything we do.

QUALITY AT THE HEART OF EVERYTHING WE DO

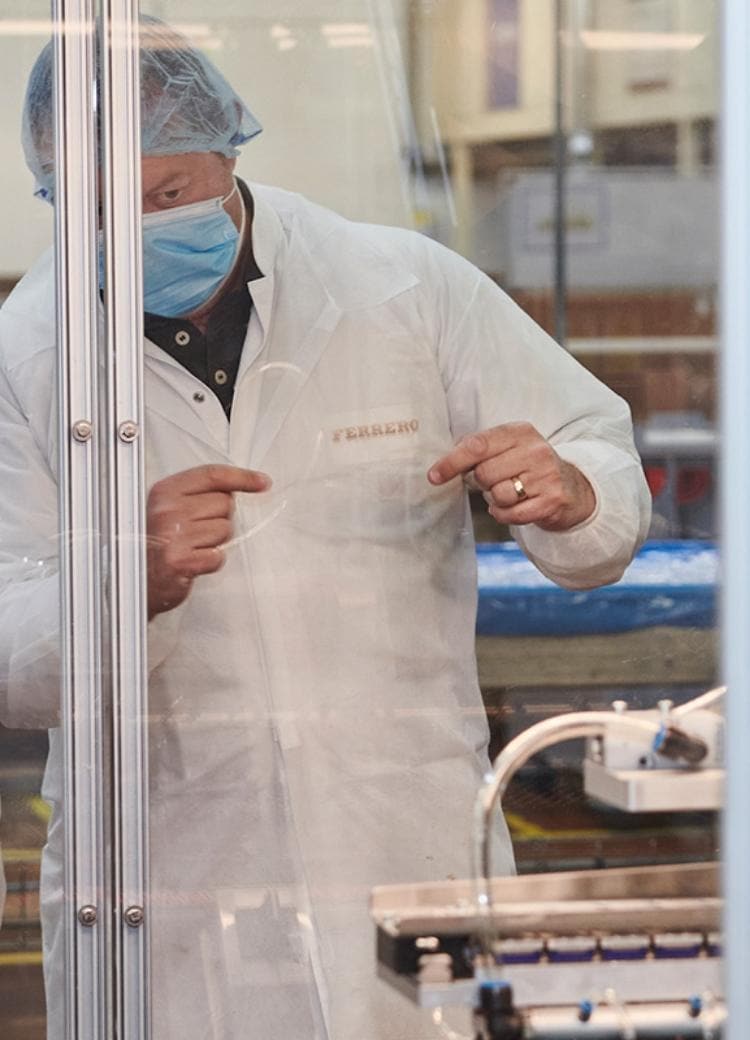

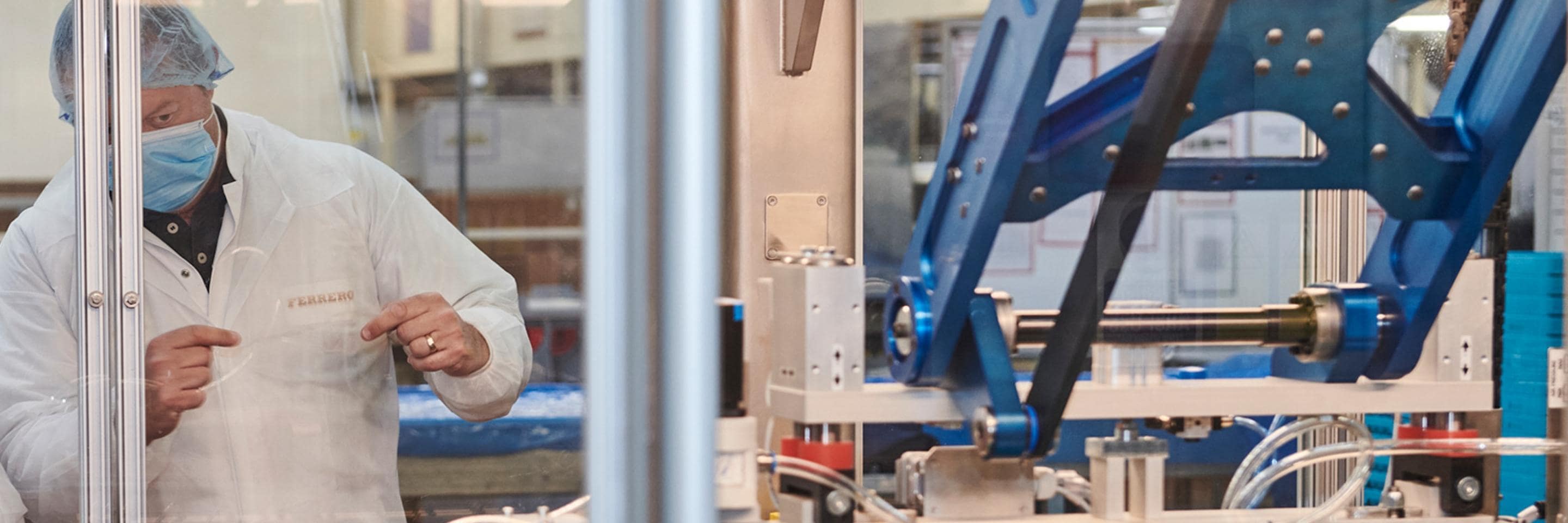

At Ferrero, we strive to know every detail about our ingredients – from their qualities and characteristics, to their origins, to the communities who cultivate them. Ferrero has developed innovative procedures, such as the so-called “sacco conosciuto”, for checking ingredients every step of the way. It is a series of processes that involve our food experts in regular safety, taste and texture checks and analyses, supplier inspections and food safety procedures to ensure a high level of quality control of raw materials.

The commitment to knowing every single detail about raw ingredients has been in the DNA of the company since it was founded in 1946. Translated literally as "known bag", this focus on fresh quality ingredients, nurtured and sourced from carefully selected suppliers and farmers, continues to inform our commitment and care for checking the ingredients every step of the way.

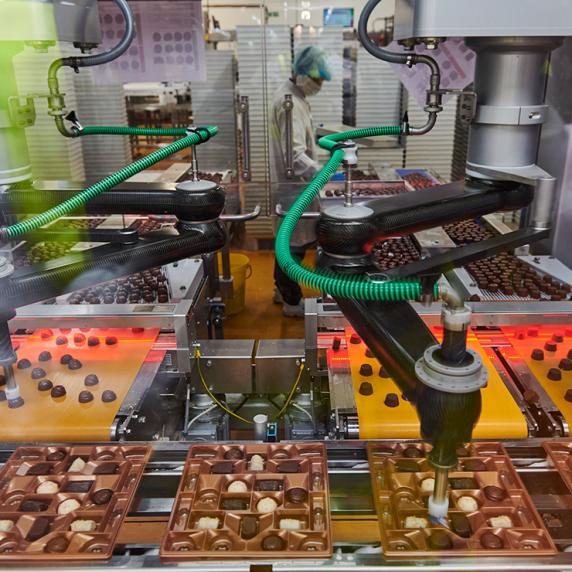

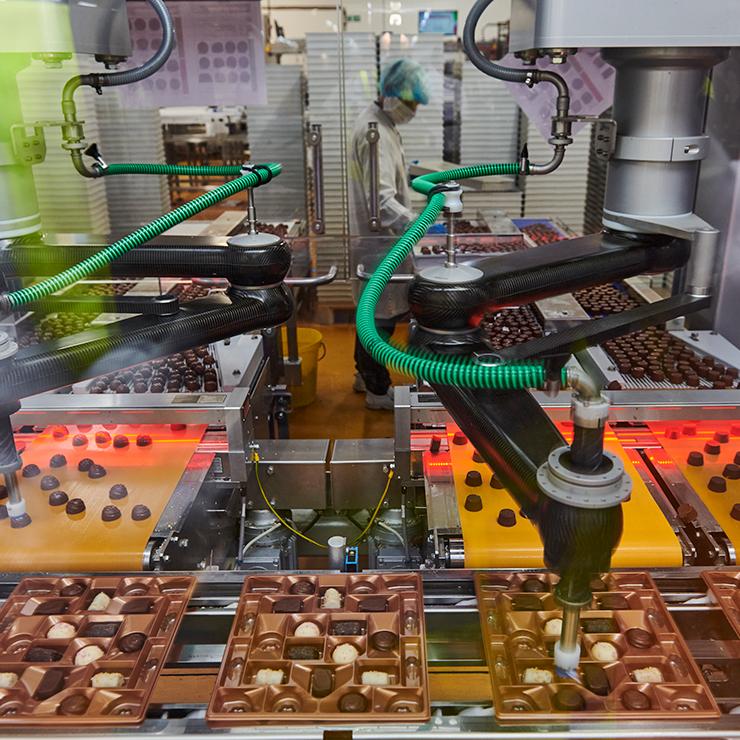

At Ferrero, we push production boundaries to ensure that the highest food safety and quality standards are implemented and to preserve the freshness and taste of every product. We are constantly adding innovative technology to our processes and are fine-tuning how our teams and machinery work together.

Our 37 manufacturing plants across the world aim to preserve freshness and deliver a hand-crafted feel from the start to the end of the line. A set of standards for the handling and processing of every product is defined centrally and adhered to in every Ferrero plant across the world to ensure that products meet high standards of quality and safety, from production to the point of sale.

We have implemented a comprehensive Quality and Food Safety Policy that outlines our strategies, competencies, and team collaboration efforts to achieve this goal. Our experts work diligently with the entire Ferrero team to ensure safe, responsible, high-quality products that offer unique consumer experiences.

Our products are manufactured in 37 factories around the world, but the central quality organization oversees the entire value chain, from raw materials to market, in close collaboration with local teams and collaborating with other departments such as R&D, Legal, Marketing, Technical departments and others.

In addition, we have a structured quality control system that covers all processes in the value chain. This system includes standardised inspections by qualified personnel in all our factories, warehouses, and subcontractors' premises to ensure the correct application of our standards and to identify opportunities for improvement.

- A panel of over 2,000 expert tasters around the globe works to ensure only the highest quality products reach our consumers.

- We test every batch of raw material received, every batch of semi-finished product and every batch of finished product in all our factories. This represents around 1.5M tests on raw materials per year.

- We measure perceived product quality at many different stages, including in store. E.g., during fiscal year 2022/23, we carried out nearly 915,000 store visits worldwide to monitor the freshness of finished products and their temperature in store.

Verification activities are defined all across the value chain to ensure the safety of our products.

All our production sites are subject to internationally recognised quality certifications schemas, ISO 9001, and FSSC 22000 (GFSI recognized) for food safety.

Within the Ferrero Toys Testing Protocol, we carry out voluntary tests over and above those required by international regulations. We also select only high-quality materials to avoid breakages and follow high design standards. In addition, we thoroughly analyse all KINDER® Surprises at the different stages of design development.

We implemented a Code of Conduct, the “Ethical, Social and Environmental Requirements for Suppliers of KINDER® Surprise Toys”. This code of conduct ensures that KINDER® Surprise toys suppliers comply with our requirements on working conditions.

A LOT TO DISCOVER